Why a Global OH&S Safety Management Standard?

There’s a critical need for organizations – regardless of size, industry or location – to improve their safety performance. Every day, 6,300 people lose their lives globally due to work-related accidents and diseases – more than 2.3 million deaths per year. Millions more are injured.

ISO 45001:2018, Occupational health and safety management systems – Requirements with guidance for use, is the much-anticipated, first global standard for occupational health and safety (OH&S) management systems. It gives organizations in the U.S. and around the world a structure to plan, support, implement and evaluate their efforts to eliminate or reduce risks to workers.

This new standard, published in March 2018, provides a framework for implementing all of their voluntary and mandated OH&S improvements. It replaces OHSAS 18001. It’s also closely aligned in its structure with ISO 9001 Quality Management Systems and ISO 14001 Environmental Management Systems so organizations can efficiently integrate ISO 45001 requirements into their existing management systems.

How have safety signs evolved over the past 100 years?

See our timeline of safety sign best practices.

Benefits of ISO 45001

Similar to how ISO 9001 and ISO 14001 have provided consensus solutions to quality management and environmental protection questions in the global marketplace, ISO 45001 is expected to drive solutions that will help improve workplace safety around the world.

Implementing and adopting an OH&S management systems approach means that your company can benefit from:

- Reduced work-related injuries and fatalities

- Eliminated or minimized OH&S risks

- Improved OH&S performance and effectiveness

- Increased worker engagement through their participation in the certification process

- Demonstration of corporate responsibility and meeting supply chain requirements

- Protection and improvement of brand reputation

"ISO 45001 will level the playing field for worker safety and health in organizations and their supply chains around the world. It will also create opportunities for organizations to create value, integrating safety, health, quality, environmental and asset (maintenance) management using a consistent risk-based approach,” says Kathy A. Seabrook, member of the U.S. Delegation to PC 283/ISO 45001 and Vice chair of the U.S. ISO 45001 Technical Advisory Group (TAG).

Clarion Safety’s Role in Leading the Way

At Clarion Safety, because of our deep commitment to reducing risk and protecting people, we’ve been involved in the development process of ISO 45001 since its start in July 2013. We’re proud to have been a part of this effort – a collaboration by more than 70 countries. We’re an active member of the U.S. TAG for ISO 45001, and have been since early in the standard’s development process. Both Clarion Safety’s founder, Geoffrey Peckham, and our head of standards compliance, Angela Lambert, have made significant contributions to preparing U.S. TAG positions for each draft of ISO 45001. Our Director of Business Development, Derek Eversdyke, continues to be involved in key decision points related to the standard as a more recent member of the TAG.

ISO 45001, Safety Signs, and a Systems Approach

As your company looks to implement processes to continually improve workplace safety in line with ISO 45001 OH&S management system objectives, the ability to accurately communicate residual risks to workers, subcontractors and guests becomes critically important. This is why safety sign systems are an important part of an ISO 45001 risk communication/risk reduction strategy. When hazards can’t be eliminated from an area or designed out of a process, intelligently designed facility safety sign systems are a means to communicate residual risk and reinforce procedures, safety training and the use of PPE. Implementing a safety sign system demonstrates that your ISO 45001 safety program is being pursued in earnest and is being continuously improved.

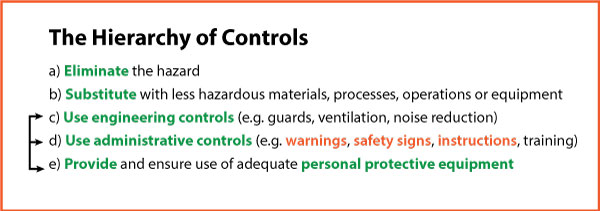

When establishing a process for risk reduction using a hierarchy of control, safety signs can be used as a type of administrative control. For hazards that cannot be eliminated, the last three risk reduction techniques are often used in combination with each other. In this way, today’s best practice safety sign systems reinforce engineering controls, training and the use of PPE.

How Clarion Can Help Your Company

Clarion specializes in providing cutting-edge facility safety communication through a guided, streamlined application of standards experience. We’re ready to listen to your needs, and help identify visual safety communication challenges and gaps. Your end result is a facility safety system that’s up-to-date with today’s risk communication technology and ANSI/ISO best practices – for a more productive, safer work environment.