How to Communicate Electrical Hazard Risks

The National Fire Protection Association’s (NFPA) 79 standard requires enclosures that do not clearly show that they contain electrical devices to be marked with a safety sign in accordance with the ANSI Z535 standards. Given that these standards made the older OSHA sign formats obsolete in 2002, if you are responsible for electrical safety you must use the newer OSHA-endorsed ANSI Z535 safety sign formats required by NFPA 79. The goal, here, is not just to comply with standards; it’s to more effectively communicate risks associated with electrical panel hazards so they can be avoided. The newer ANSI Z535-formatted signs do this job better than what has been used in the past for this purpose.

What is an Electrical Enclosure?

An electrical enclosure is a cabinet or box that protects electrical or electronic equipment (displays, knobs, or switches) and prevents electrical shock or explosions. Enclosures are usually made from rigid plastics or metals like steel, stainless steel, or aluminum. Enclosures are rated to designate protection against hazardous, non-hazardous, and other specific environmental conditions.

Enclosures protect electrical equipment in a variety of industrial and utility applications. They may also shield equipment from electromagnetic and radio frequency interference. If the enclosure is damaged, then the electrical equipment or wiring can become exposed and pose a hazard to those near it. Enclosures are often used to protect the following types of equipment:

- Circuit breakers, contactors, control panels, and switches

- Distribution boards and panelboards

- Pressurization and purging equipment and systems

The ANSI Z535 Difference

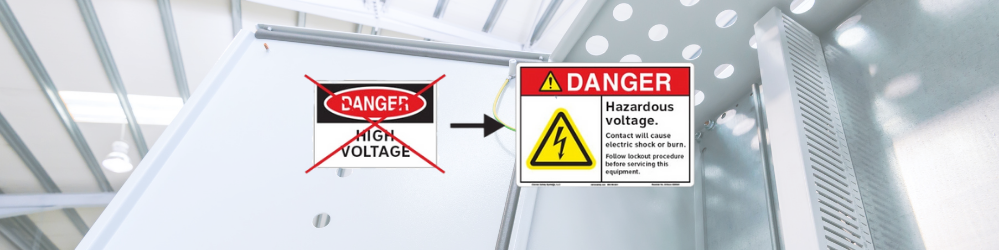

Lives are on the line and the use of Clarion Safety’s state-of-the-art electrical safety signs to meet the NFPA requirement is the right choice. Our signs combine the newest ANSI Z535 sign formats with the globally standardized ISO/IEC electrical hazard symbol. More substantive, explanatory text is added to yield a more informative sign when compared to the old “DANGER – HIGH VOLTAGE” signs. Know that you can customize your electrical enclosure safety signs to bring them perfectly into line with your company’s procedures.

NFPA 79 on Electrical Enclosure Safety Signs

NFPA 79 (2015 edition) states the following in section 16.2 Safety Signs for Electrical Enclosures:

- 16.2.1 Enclosures that do not clearly show that they contain electrical devices shall be marked with a safety sign in accordance with ANSI Z535 series, which deals with product safety signs.

- 16.2.2 Safety signs shall be plainly visible on the enclosure door or cover.

- 16.2.3 Electrical equipment for industrial machines, such as industrial control panels and the enclosures of disconnecting devices, shall be marked with a safety sign in accordance with ANSI Z535.4 to warn qualified persons of potential electric shock and arc flash hazards.

- 16.2.3.1 The marking shall be located so as to be clearly visible to qualified persons before examination, adjustment, servicing, or maintenance of the equipment.

- 16.2.3.2 It shall be permitted to omit safety signs where the size of the enclosure precludes placement of the label on the enclosure (e.g., operator-machine interfaces, control stations, position sensors).

- 16.2.4 A safety sign shall be provided adjacent to the disconnecting operating handle(s) where the disconnect(s) that is interlocked with the enclosure door does not de-energize all exposed live parts when the disconnect(s) is in the open (off) position.

- 16.2.5 Where an attachment plug is used as the disconnecting means, a safety sign shall be attached to the control enclosure door or cover indicating that power shall be disconnected from the equipment before the enclosure is opened.

- 16.2.6 Where the disconnecting means is remote from the control enclosure, a safety sign shall be attached to the enclosure door or cover indicating that the power shall be disconnected from the equipment before the enclosure is opened and that the enclosure shall be closed before the power is restored.