OSHA’s Top 10 Violations for 2019

Posted by Clarion Safety Systems | 12th Sep 2019

OSHA’s Top 10 Violations for 2019

Annual Workplace Safety Data from OSHA and NSC

The Occupational Safety and Health Administration (OSHA) and the National

Safety Council (NSC) have long stood as the watchdogs for American businesses

when it comes to safety guidance and regulation. A government entity and the

product of 1970s legislation, OSHA's mandate is improving workers' physical

well-being while on the job through a combination of oversight, training,

educational initiatives and enforcing key standards proven to reduce the risk

of injury.

Preceding OSHA, NSC has served as the U.S.' leading safety advocate for more than a century. A non-profit organization, NSC promotes the health and well-being – both physically and mentally – of Americans in virtually all arenas of life, including at home, on the road, within communities or on the job.

Combined, OSHA and the NSC form quite the tag team – the former charged with developing key safety standards for business places and the latter, in part, hammering home the message through evidence-based best practices and statistics showcasing the effectiveness of safety initiatives and legislation.

OSHA’s Annual Top 10 List

Every year, though, whether due to careless mistakes or workplaces skirting

their safe standard adherence duties, OSHA violations occur. These breaches to

safety rules are chronicled and announced by OSHA annually in order for

workplaces to understand key areas to focus on to keep workers safer. OSHA

typically releases a preliminary "Top 10” list of the most frequently

cited safety violations for that fiscal year (FY) as part of NSC’s annual

Congress and Expo.

One of the most troubling aspects of this list is the fact that, almost without fail over the past several years, the same violations come up again and again – many of them even in the same order, listed from the most to least common. This suggests that, for all the strides being made every day in the field of safety and regulatory oversight, many of the most common challenges have yet to be conquered.

Recapping the 2016, 2017 and 2018 OSHA Violation Lists

Take the 2016, 2017 and 2018 OSHA violation lists as examples. The top five

most common violations are identical: fall protection, hazard communication,

scaffolding, respiratory protection and lockout/tagout. Many of the following

five violations are also the same, just moving up or down in prevalence on the

list.

It’s a telling benchmark that these top hazards are still a concern year over year, despite OSHA’s push to communicate and regulate, as well as the shared goal of increased safety for today’s workplaces and equipment manufacturers.

Top 10 OSHA Violations for FY 2019

This past week at NSC’s Congress and Expo in San Diego, CA, OSHA's Deputy

Director of the Directorate of Enforcement Programs, Patrick Kapust, announced

the agency’s preliminary list of violations for FY 2019.

“Look at your own workplace and see where you can find solutions,” Kapust said during the presentation. “These are common violations. They’ve been around for a while. The answers are out there.”

Here's a summary of the 2019 top violations – and some of the safety communication steps you can take to keep people in your workplace or who use your equipment safer.

Violation #1: Fall Protection – General Requirements

For the ninth consecutive year, fall protection has topped the annual hazard

list, with 6,000 safety violations. The OSHA standard 1926.501 outlines fall

protection system requirements, designed to protect employees on walking or

working surfaces with an unprotected side or edge 6 feet off the ground or

higher.

Clarion Safety Solution: Injuries that occur as a result of slips and falls are among the most common in the country, not just at the workplace. Safety warnings can inform workers, guests and contractors of potential unsafe slip and fall hazards, and reinforce and remind employees about proper safety procedures and personal protective equipment (PPE) requirements. Clarion Safety has the trip hazard signs and slip, trip and fall labels you need to send the right message in clear, concise ways.

Violation #2: Hazard Communication

When potentially harmful chemicals and/or substances are present, it’s the job

of business owners and product manufacturers to make this fact apparent.

Effective as of 2012, the 1910.1200 OSHA standard has been updated to

correspond with the United Nations Globally Harmonized System of Classification

and Labeling of Chemicals (GHS). GHS establishes a common way of communicating

chemical hazard information including the use of a very standardized approach

to the content and structure of safety labels pertaining to chemical products.

Clarion Safety Solution: It isn't enough to merely reference that chemicals are nearby; GHS graphical symbols help with quick, easy comprehension in a standardized manner. Clarion Safety has you covered with the GHS labels you need, with pictograms covering hazards and meanings like carcinogens, flammables, irritants, gases under pressure, explosives, skin corrosion/burns, oxidizers and aquatic toxicity.

Violation #3: Scaffolding

This OSHA standard,1926.451, relates to general safety requirements for

scaffolding. Employers are required to protect construction workers from falls

and falling objects while working on or near scaffolding – temporary structures

composed of polls and planks – at a 10 foot height or higher.

Clarion Safety Solution: Keep your hard-working construction team off the injured list by selecting from Clarion Safety’s comprehensive workplace safety signs, including slip, trip and fall signs.

Violation #4: Lockout/Tagout

OSHA standard 1910.147 refers to injury risks that exist through the use of

power equipment, such as scroll saws or other machinery that uses voltage. It

requires employers to establish a program and utilize procedures for affixing

appropriate lockout/tagout devices to energy isolating devices, and to disable

machines or equipment to prevent unexpected energization, start up or release

of stored energy in order to prevent injuries. You'll notice this 1910 standard

as a recurring theme in the violations list over the years, and the 2019

iteration was no different. This year, lockout/tagout accounted for 2,600

violations.

Clarion Safety Solution: Devastating injuries can occur from electrical hazards. Proper identification of the nature of electrical hazards and specific avoidance procedures with warnings that give the viewer more information are key to making products and workplaces safer. Clarion Safety has the lockout/tagout safety labels, signs and tags – as well as electrical safety labels, signs and tags – needed to keep people safe.

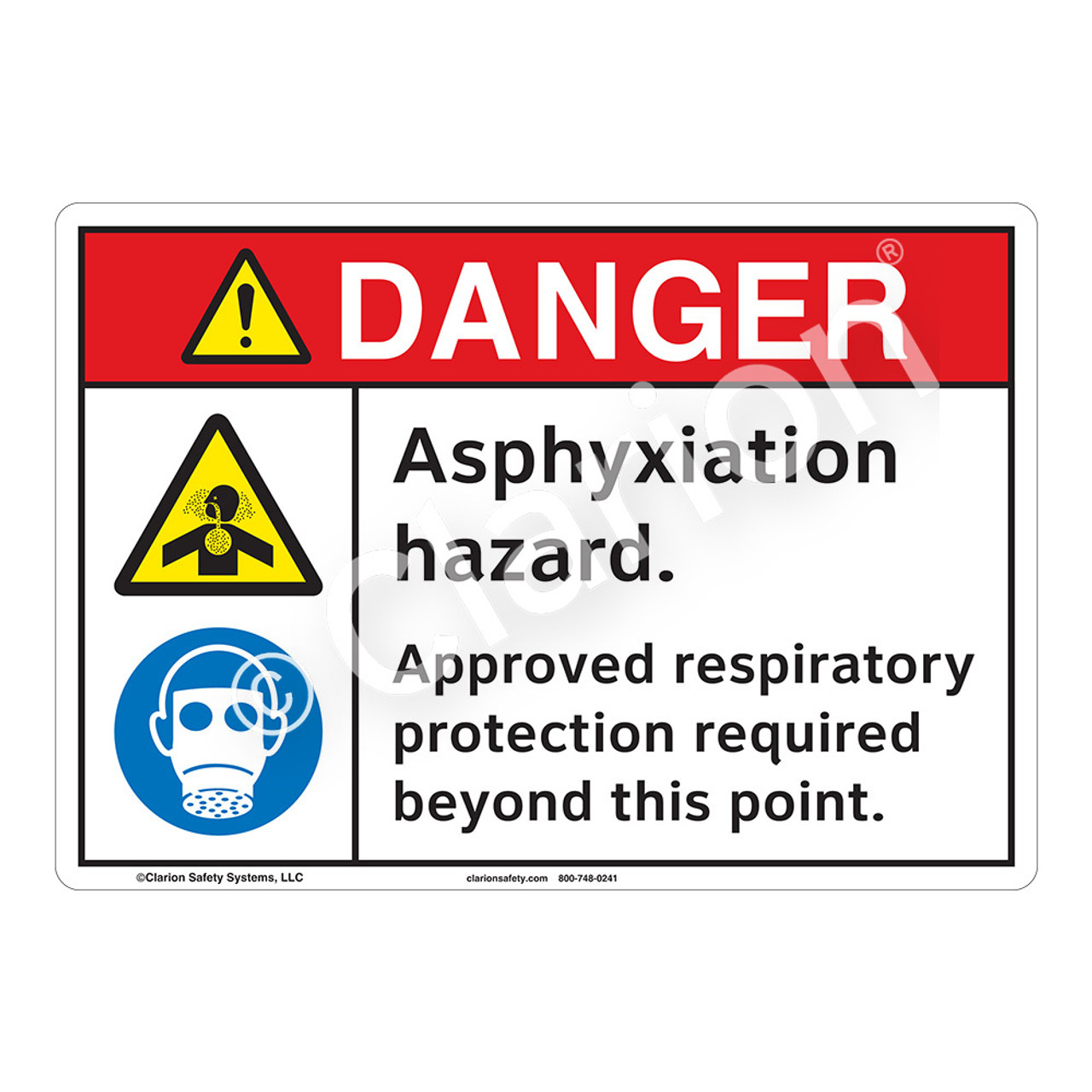

Violation #5: Respiratory Protection

At high elevations or in environments where air quality is less than stellar,

employers must utilize respiratory protection systems that reduce the risk of

inhaling fumes, smoke and mists. OSHA standard 1910.134 outlines these

requirements in more detail.

Clarion Safety Solution: Use personal protective equipment (PPE) signs to provide permanent visual reinforcement of your facility’s safety training policies requiring PPE, like respirators. Browse our PPE reinforcement signs now.

Violation #6: Ladders

Ladders: they're so common in work environments, there’s an entire month

devoted to promoting how to use them properly, given that ladders are often

developed differently depending on their function. OSHA standard 1926.1053

outlines what some of these general safety requirements include.

Clarion Safety Solution: Ascending steps or rungs come with risk, even when a few inches off the ground. You can communicate these potential dangers with Clarion Safety’s slip, trip and fall safety signs .

Violation #7: Powered Industrial Trucks

From platform lift trucks to fork trucks and those built for over-the-road

hauling, OSHA standard 1910.178 covers the safety requirements for these

hulking pieces of machinery.

Clarion Safety Solution: It isn't just the people using powered industrial trucks and forklifts that need protection but the people around them. Clarion Safety has the forklift safety labels and signs you need to protect workers, visitors, and subcontractors from forklift traffic accidents and injuries.

Violation #8: Fall Protection - Training Requirements

This violation was new to the violations list in 2017. It seems this year

that employers are still struggling to provide the proper training materials

and programs for employees as it relates to fall protection.

Clarion Safety Solution: Support your fall prevention program and reinforce training on proper safety procedures with safety labels and signs. Clarion Safety offers a variety of trip hazard signs and slip, trip and fall labels – and we can create unlimited custom options in line with your specific program or hazards.

Violation #9: Machine Guarding

The OSHA standard,1910.212, covers general requirements for machine guards to

protect the operator and other employees in the machine area from potential hazards

that can occur during a machines operation or maintenance, such as in-running

nip points, rotating parts, flying chips and sparks.

Clarion Safety Solution: Post safety labels and signs to warn of potential hazards if guards, interlock switches or other safety devices are circumvented. Well-designed safety labels and signs are your critical communication tools to reinforce training, serving as a final reminder regarding the importance of the safety devices installed on your products or in your facilities.

From emergency stop legend plates to guard switch light curtain labels to accident prevention and equipment safety signs, we can meet all your warnings needs.

Violation #10: Eye and Face Protection

2018 was the first year that this violation “Personal Protective and Lifesaving

Equipment - Eye and Face Protection” made the list, and it’s returned again in

2019, with over 1,400 violations. OSHA standard 1926.102 requires that

employers ensure that their employee use appropriate eye or face protection

when exposed to eye or face hazards from flying particles, molten metal, liquid

chemicals, acids or caustic liquids, chemical gases or vapors, or potentially

injurious light radiation. Kapust has said that these violations often involve

the wearer using prescription lenses in addition to PPE, leading to obscured

views.

Clarion Safety Solution: Use safety labels and signs to remind employees about the hazards at hand and the proper PPE required. Clarion Safety offers a variety of PPE labels and PPE reinforcement signs that offer important visual reminders of your company’s safety policies regarding safety glasses and face protection.

What This Year’s Report Means for Safety

Safety at work requires everyone putting their best foot forward. NSC president

and CEO Lorraine M. Martin is confident that business owners and their

employees can break the vicious by getting serious about safety.

“Far too many preventable injuries and deaths occur on the job,” Martin says. “The OSHA Top 10 list is a helpful guide for understanding just how adept America’s businesses are in complying with the basic rules of workplace safety. This list should serve as a challenge for us to do better as a nation and expect more from employers. It should also serve as a catalyst for individual employees to recommit to safety.”

Clarion Safety has the labels, signs and tags that can help your warnings to get noticed and heeded. We also offer easy, online custom product designer tools – allowing you to create custom safety labels and custom safety signs in three simple steps. And, we offer complementary services like label and sign assessments, as well as risk assessments. Contact us today to learn more!

This blog was originally posted on 10/31/2018 and updated with new information.